THE

SUB-FLOOR

EZ-Cool Heat and Sound Insulation, ¾ of 1 roll

Southern Pine Tongue-and-Groove Plywood 48”x

96” x 0.719” – 3 sheets for $93

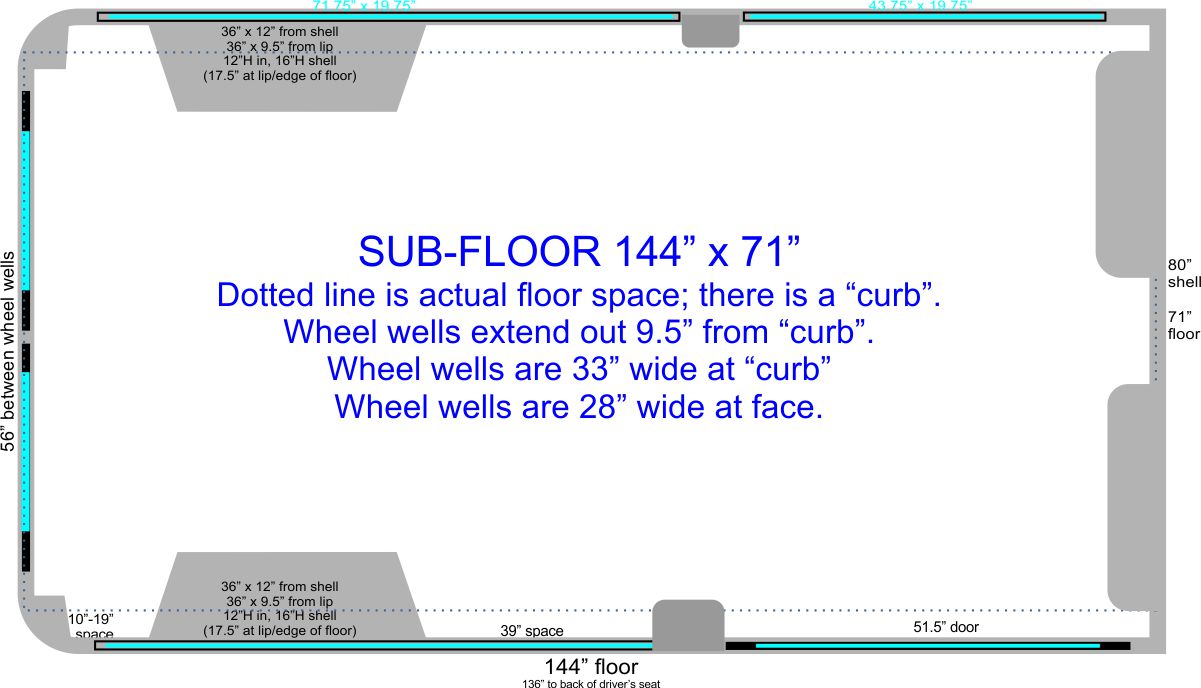

Maxx has a big floor. 6 feet

wide and 12 feet long.

Ya.

Twelve feet.

And that’s just to the back of the

front seats.

(The full van is 19’6”

bumper-to-bumper.)

That’s 72 square feet of floor.

Maxx has a big floor. 6 feet

wide and 12 feet long.

Ya.

Twelve feet.

And that’s just to the back of the

front seats.

(The full van is 19’6”

bumper-to-bumper.)

That’s 72 square feet of floor.

But it’s

not a complicated floor.

Only the rear wheel wells get in the

way, and they were simple trapezoidal cut-outs. There

is no step at the side door, so that’s not an

issue either.

ProMasters are front-wheel-drive vans,

so, with no drive-shaft running underneath to

the rear wheels, the floor sits lower.

This gives the PM a taller cargo bay

than Sprinter or Transit, topping out at a

Rick-can-stand-up-straight 6’4”, and an

impressive-sounding 456 cubic feet of cargo (or

living) space.

Maxx came

with a thin rubber floor and, as part of the the

temp décor, I laid a cheap green rug over it. No way

that was going to suffice, though.

Aside from the noise and heat of the

sheet metal, there was going to have to be

something that I’d be able to screw 2x4’s into

when I get around to building my furniture. And

there would be tile laid on top of it in one of

the very last steps of The Project.

Hence, the

plywood. Three

48" x 96" sheets of 23/32” slotted pine.

The 4-foot widths were a perfect fit in

the 12-foot bay; each just had to have two feet

of length sawed off. The middle one needed

a slight trim where the Big Rib was (just behind

the sliding door), and the back sheet needed

some extra cuts for the wells.

The

slotted sheets were key for avoiding separations

between the sheets. With their tongues

tightly in their grooves, the uniform level of

the floor was guaranteed. With a

peel-and-stick tile in the future plans, that

would matter a lot.

But before

any of that would get done, there was EZ-Cooling

to do. Many

of the videos that I watched stressed the

importance of having a layer of insulation under

the sub-floor in order to keep heat in.

Huh?

Keep it in??

Why would I want to do that?

Those folks were all into that weird

winter stuff and, thus, needed to keep the van

toasty when they boondocked out near the ski

areas and such.

Rotsa ruck to them, I say.

When winter rolls around, me be

Florida-bound.

Besides,

warm air rises, so how does floor insulation

help anyway?

Well, some videos claimed that, while

it didn’t help with the temperature all that

much, it earned most of its keep as a layer of

padding under the plywood.

The plywood was pretty damn heavy, so

its own weight would keep it from moving much,

but having that layer of EZ-Cool under it

eliminates all that wood-on-metal rattle.

I drove up

to Cape Coral to get my plywood.

I also drove up there to get my

workshop. B&J,

my erstwhile Key West besties, bought a house up

there, and it has a garage and a driveway. I

deemed those to be perfect for this kind of

work, and invited myself up to pay them an

overdue visit.

Turns out, Brian

and I did all the work out in the South Florida

sunshine. The

EZ-Cool took just a few minutes to do.

We used the green rug – which had been

cut to fit snugly – as our template, marked the

outline on the EZC with a Sharpie, cut it with a

box cutter, sprayed 3M-90 on the underside and

on the rubber floor, and stomped it down.

Turns out, Brian

and I did all the work out in the South Florida

sunshine. The

EZ-Cool took just a few minutes to do.

We used the green rug – which had been

cut to fit snugly – as our template, marked the

outline on the EZC with a Sharpie, cut it with a

box cutter, sprayed 3M-90 on the underside and

on the rubber floor, and stomped it down.

Then, we

used the open back doors of the van as our work

table, sawing the plywood cuts just behind the

rear bumper, and hefting the planks into place

right from there.

Some more 3M-90 was applied to the

underside of the wood and to the top of the EZC,

just because, well, why not?

We fit the tongues of the back two

sheets into the grooves of the front two sheets,

and we were done!

What would I

have done differently?

Well, part of me wanted to bolt the floor down. That

was actually the plan.

I

didn't realize it until everything was out of

the van, but if I removed the handful

of floor-level OEM tie-downs that came with the

van, I could have used the existing holes to

drill up through the wood and used t-nuts to

lock it down.

There would have been no metal drilling to do,

and the bolt/washer would have sealed the hole

against corrosion. That probably would

have been the most significant benefit.

The floor itself was not going anywhere; it

would be bolted and screwed to things that

were bolted and screwed directly to the

frame. I kinda wish I had done

it, but at the time, well, it was getting

mighty hot out, the floor was damn

stable as it was, crawling under Maxx wasn’t

that appealing, annnnd we had another big fish

yet to fry: the solar panel installation.